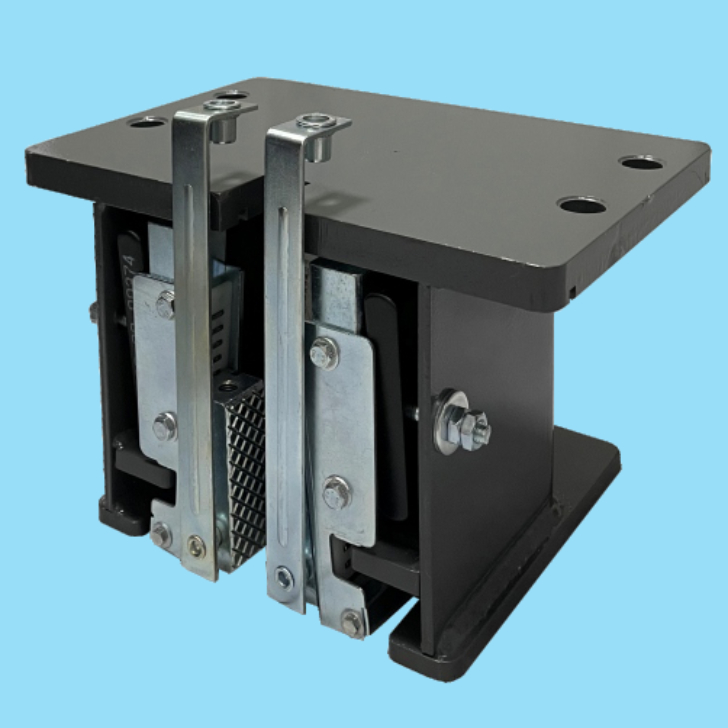

The Elevator Buffer: Safeguarding Against Impact

In the hierarchy of elevator safety components, the buffer stands as a critical last line of defense. Installed at the bottom (and sometimes top) of the elevator shaft, this device is designed to absorb impact energy and reduce the force of a sudden stop if the elevator car or counterweight overshoots its normal range of motion.

Types of Elevator Buffers

Elevator buffers primarily fall into three categories, each suited to different elevator speeds and usage scenarios:

- Spring Buffers: Utilizing coiled steel springs, these are ideal for low-speed elevators (up to 1 m/s). The springs compress upon impact, gradually dissipating energy.

- Hydraulic Buffers: Employing oil-filled cylinders, they are commonly used in medium to high-speed elevators. The hydraulic fluid flows through small orifices during compression, converting kinetic energy into heat to cushion the impact smoothly.

- Polyurethane Buffers: Made from durable elastic materials, these lightweight buffers are suitable for low to medium speeds and offer excellent resistance to wear and environmental factors.

How Buffers Work

When an elevator exceeds its intended travel range and strikes the buffer, the device engages to decelerate the car gradually. Spring buffers rely on elastic deformation, while hydraulic models use fluid dynamics to control the deceleration rate. Both mechanisms ensure that the impact force remains within safe limits, protecting passengers from injury and preventing structural damage to the elevator.

Maintenance Essentials

Regular inspection and maintenance are vital to buffer performance. For hydraulic buffers, checking oil levels, seals, and fluid condition is crucial—leaks or contamination can impair functionality. Spring buffers require examination for corrosion, deformation, or breakage. Polyurethane buffers need inspection for cracks or hardness changes due to aging. Maintenance should align with manufacturer guidelines and regulatory requirements.

Compliance with Safety Standards

International standards (e.g., ISO 8100) and local codes mandate strict specifications for buffer design, energy absorption capacity, and installation. These standards ensure buffers can handle the maximum impact loads specific to the elevator’s speed and weight, providing reliable protection in emergency scenarios.

Innovations in Buffer Technology

Modern advancements focus on enhancing durability and performance. New hydraulic buffer designs feature improved seals to prevent leaks, while polyurethane materials are engineered for longer lifespans. Some systems now include sensors to monitor buffer condition in real time, enabling predictive maintenance and reducing downtime.

Conclusion

The elevator buffer may operate in obscurity, but its role in safety is irreplaceable. By absorbing impact energy during unexpected overtravel, it mitigates risks to passengers and equipment alike. Regular maintenance, adherence to standards, and adoption of innovative designs ensure this critical component remains effective when it matters most.