- Home

- Shop

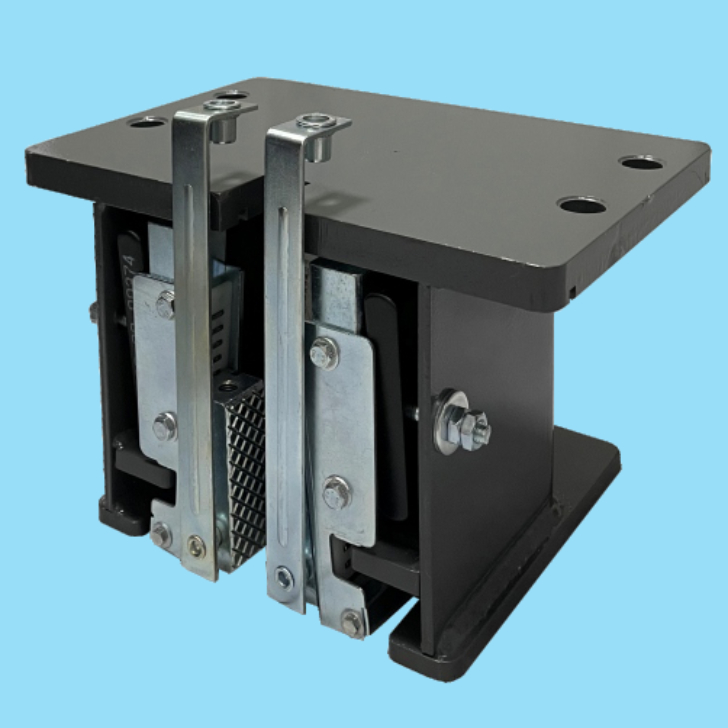

- Progressive Safety Device

Description

Unlike the instantaneous safety gear that brings the elevator to an abrupt stop, the progressive safety gear operates by gradually increasing the braking force. When the elevator exceeds the set speed or gets out of control, the progressive safety gear is triggered. It utilizes a series of mechanical structures, such as wedges and springs, to generate a braking effect. As the elevator continues to move, the braking force gradually grows, making the elevator slow down steadily until it comes to a complete stop. This gradual braking process effectively reduces the impact on the elevator car and passengers, minimizing the risk of injury or damage to the elevator structure.

Advanced Variable products with swatches

Products variations colors and images without any additional plugins.

- Instantaneous safety pliers

Description

The instantaneous safety gear is a vital safety device in elevators. Its main function is to quickly brake the elevator car when the elevator overspeed exceeds a certain limit or other dangerous situations occur, preventing the elevator from falling and ensuring the safety of passengers.

- tension device

Description

A key component in elevators, the tensioning device maintains proper tension of hoisting ropes, compensation ropes and related cables. It works via its own weight or mechanical adjustment, preventing rope slack, slippage and ensuring stable, safe elevator operation. - buffer

Description

When an elevator exceeds its intended travel range and strikes the buffer, the device engages to decelerate the car gradually. Spring buffers rely on elastic deformation, while hydraulic models use fluid dynamics to control the deceleration rate. Both mechanisms ensure that the impact force remains within safe limits, protecting passengers from injury and preventing structural damage to the elevator.

- Progressive Safety Device

- About us

- Blog

- Contact us